T °Imager

The

The

The baseline

Most of the

Explore

Gallery | Data Analysis | Benefits | Applications |

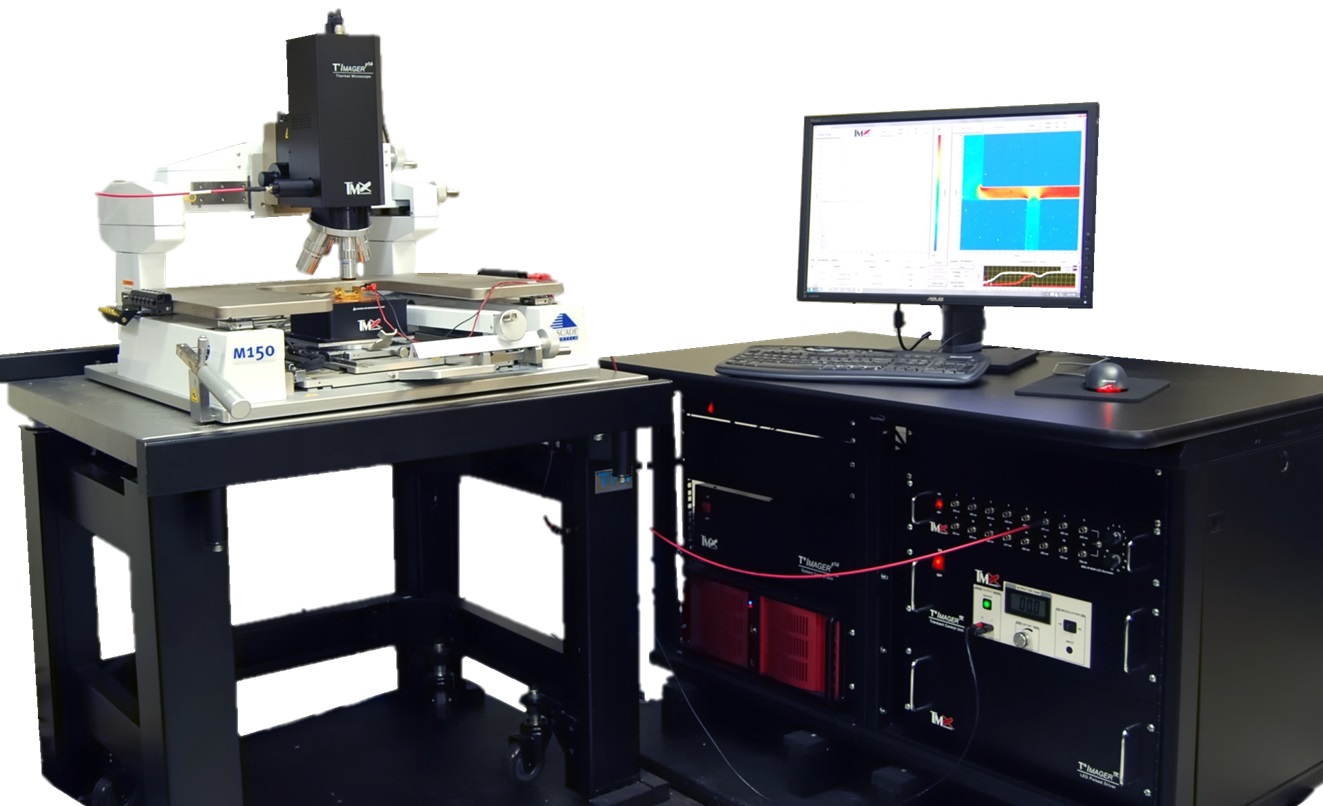

T °Imager® Models

T °Imager® P14

Quiet, compact design for non-invasive, deep-submicron temperature mapping using selectable visible light.

Gallery

Data Analysis

The

TMX Scientific also offers

Benefits

- Large thermal image size: up to

1000×1000 pixels - Superior spatial resolution: up to

0.2 µm (7.8E-6 in.) - Speed: full, submicron thermal image in seconds

- Temperature accuracy: Better than 3% of measured temperature change

- Turn-key operation

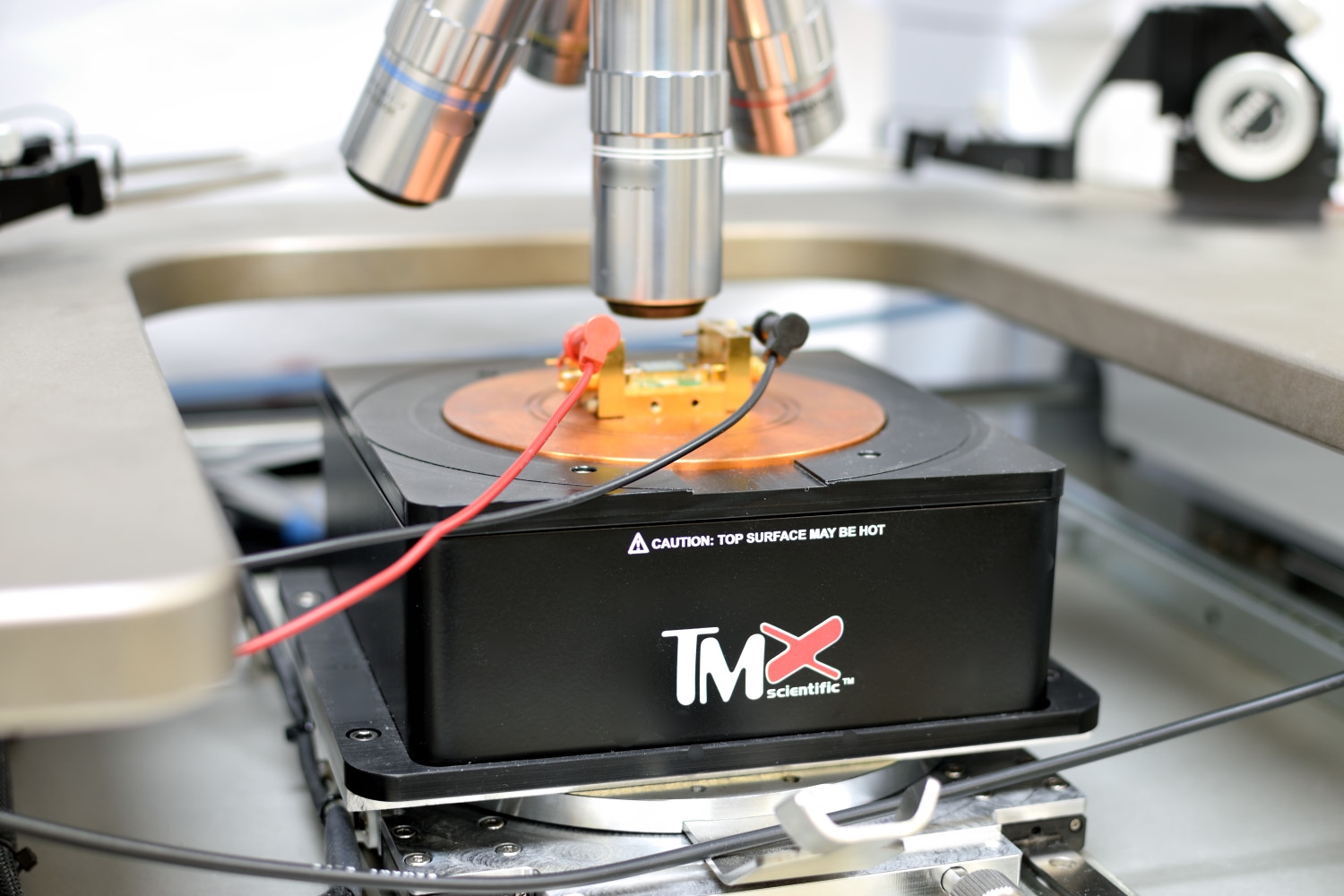

- No surface treatment or painting required

- Measure materials that are transparent to infrared

- Non-contact, fully optical approach

- Great flexibility: adjustable triggering for device activation

- Transient capability (with Transient Package)

- Novel pixel-by-pixel calibration (with

T°Pixel™ and Calibration Package) - Nanoscale dynamic alignment (with

T°Pixel™ or Calibration Package)

Applications

- Measure the surface temperature fields of active electronic and optoelectronic devices, MEMS

- Measure the surface temperature fields of any type of externally modulated and controllable heated microscale structures

- Validate thermal design of microelectronic devices and ICs

- Perform quality control based on thermal imaging

- Locate hot spots and measure amplitude at device level

- Diagnose defects that generate hot spots

- Measure electroluminescence emission